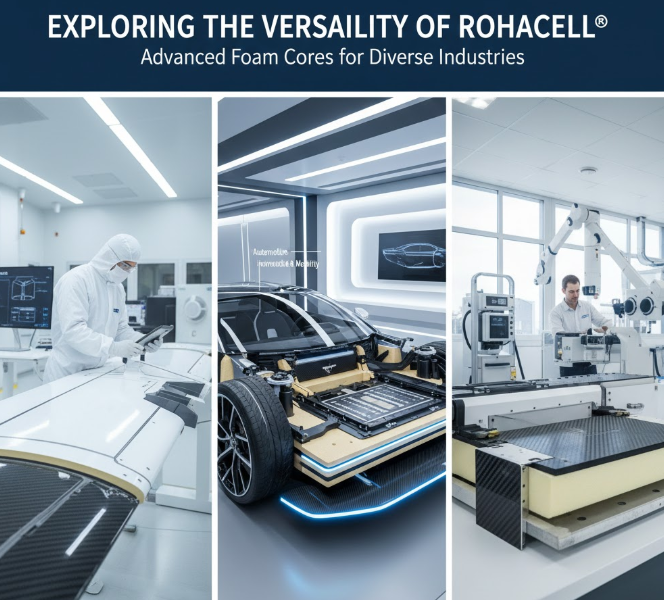

Some materials find their niche in a single industry and remain there indefinitely. Others demonstrate properties so broadly useful that engineers across multiple sectors adopt them for entirely different applications. ROHACELL® PMI foam falls firmly in the second category. What began as an aerospace material has spread into automotive, sports equipment, medical devices, renewable energy, and electronics—each industry leveraging the foam’s distinctive combination of low density, high strength, and thermal stability.

The Foundation: PMI Chemistry

Understanding ROHACELL®’s versatility starts with its chemistry. Polymethacrylimide represents a unique polymer class that forms rigid, closed-cell foams with exceptional mechanical properties even at very low densities. The material can be produced in density grades ranging from around 30 kg/m³ to over 200 kg/m³, allowing engineers to select the optimal balance of weight and strength for each application.

The closed-cell structure prevents moisture absorption that plagues some alternative core materials. This characteristic matters enormously in applications where weight gain from absorbed water could degrade performance or where freeze-thaw cycles might damage the structure. Aircraft components, marine equipment, and outdoor sporting goods all benefit from this inherent moisture resistance.

Aerospace and Aircraft Applications

The aerospace industry discovered PMI foams first, and these applications remain among the most demanding. Aircraft certification requirements impose rigorous testing and qualification standards that few materials can meet. ROHACELL® WF was developed specifically for this environment, conforming to MIL and CMS specifications while delivering the mechanical performance aircraft structures require.

Current aerospace applications span virtually every aircraft subsystem:

- Primary structures including pressure bulkhead stringers and floor panels

- Control surfaces where weight directly affects aircraft handling

- Radome structures requiring both structural performance and electromagnetic transparency

Helicopter manufacturers have become particularly enthusiastic users. Rotor blades represent one of aviation’s most demanding structural applications, combining high fatigue loads with precise aerodynamic requirements. PMI foam cores enable blade designs that would be impractical with heavier materials, while their resistance to creep ensures dimensional stability throughout the blade’s service life.

Automotive Integration

The automotive industry approaches materials differently than aerospace. Production volumes are orders of magnitude higher, cost sensitivity is acute, and manufacturing processes must support rapid cycle times. Nevertheless, the drive toward lighter vehicles has opened doors for PMI foams in applications where their performance justifies the material cost.

Structural applications include crash structures where the foam’s energy absorption characteristics complement composite face sheets, as well as underbody panels that benefit from the combination of stiffness and light weight. Semi-structural applications like interior trim panels and load floors leverage the material’s formability—PMI foam can be thermoformed into complex shapes, allowing designers freedom that sheet metal cannot match.

Electric vehicle development has accelerated automotive adoption considerably. Battery pack enclosures benefit from lightweight construction that maximizes range, while thermal stability ensures the core material withstands battery heat without degradation. Some manufacturers specify high-performance PMI grades for structural battery housings where crash protection and thermal management intersect.

Sports and Leisure Equipment

Performance sporting goods represent a natural fit for advanced materials. Athletes and enthusiasts willingly pay premium prices for equipment that offers even marginal performance advantages. The sports industry has pioneered some of the most creative applications of PMI foam technology, pushing material capabilities in ways that sometimes influence more conservative sectors.

Notable applications include:

- Racing bicycle frames and components where grams saved translate to competitive advantage

- Ski and snowboard cores requiring torsional stiffness with vibration damping

- Racquet frames for tennis, badminton, and similar sports demanding precise weight distribution

Water sports equipment has embraced foam-cored composites extensively. Racing sailboats, surfboards, and kayaks all benefit from the combination of light weight, stiffness, and moisture resistance that PMI foams provide. The marine environment is particularly harsh on materials, making the closed-cell structure’s inherent water resistance valuable.

Medical and Electronic Applications

Medical imaging equipment presents unique requirements that PMI foams address effectively. X-ray tables must support patient weight while minimizing X-ray absorption—a combination that the foam’s low density and composition satisfy naturally. The extremely fine cell structure of certain grades ensures minimal interference with imaging while maintaining structural rigidity.

Antenna and radome applications exploit PMI foam’s excellent dielectric properties. In the high-frequency domain, materials must maintain dimensional stability while presenting minimal electromagnetic interference. The HF grade was developed specifically for these applications, offering low dielectric constants combined with favorable transmission characteristics that make it ideal for satellite communication systems, radar installations, and 5G infrastructure.

The electronics sector continues finding new uses as devices shrink and thermal management becomes more critical. Drone manufacturers, for instance, appreciate how PMI foam enables lightweight airframes that maximize flight time while protecting sensitive electronics from vibration and impact.

Renewable Energy Applications

Wind turbine blades represent one of the largest-volume applications for structural core materials. While cost constraints often favor less expensive alternatives for the bulk of the blade structure, critical areas like the blade root and spar caps sometimes specify premium PMI grades for their superior fatigue resistance and creep behavior. As turbines grow larger and blade lengths extend beyond 80 meters, material performance becomes increasingly important.

The renewable energy sector’s growth trajectory suggests expanding opportunities for high-performance foam cores. Offshore wind installations face particularly demanding conditions—salt spray, extreme temperatures, and decades of continuous operation—where material durability justifies higher initial costs.

Material Selection Across Industries

The proliferation of ROHACELL® grades reflects the diversity of application requirements. Different industries—and different applications within those industries—prioritize various properties. Aerospace might emphasize temperature resistance and fire performance, while automotive focuses on processing speed and cost. Sports equipment manufacturers care deeply about specific stiffness, while medical applications prioritize radiolucency.

Working with experienced distributors helps engineers navigate the grade selection process. The technical support available from specialists who understand both the materials and the application requirements can significantly shorten development timelines and reduce the risk of specification errors.

Consider the range of processing methods alone: hand layup, RTM, vacuum infusion, and autoclave processing each impose different demands on core materials. A grade optimized for autoclave curing might perform poorly in an infusion process, and vice versa. Technical partners who understand these nuances prevent costly trial-and-error cycles.

A Track Record of Adaptation

What makes ROHACELL® particularly interesting is its continued evolution. The product family hasn’t remained static since its introduction. Evonik has developed new grades addressing specific industry needs—finer cell structures for minimal resin uptake, enhanced temperature resistance for demanding cure cycles, and optimized formulations for high-volume processing.

This ongoing development reflects the collaborative relationship between material suppliers and end users. Industries push for improved performance, and manufacturers respond with innovations that expand what’s possible. The result is a material family that remains relevant decades after its introduction while continuing to open new application territories.

Across all these industries, the underlying value proposition remains consistent: ROHACELL® enables structures that would be impossible or impractical with conventional materials. Whether the goal is a lighter aircraft, a faster bicycle, or a more sensitive imaging device, PMI foam technology provides solutions that competing materials cannot match. That versatility explains why engineers across such diverse fields have adopted what started as a specialized aerospace material.