Materials science rarely stands still, and structural foam technology is no exception. The ROHACELL® product family that aerospace engineers specified twenty years ago has evolved substantially, with new grades addressing emerging applications and manufacturing processes. Understanding where this technology is…

Some materials find their niche in a single industry and remain there indefinitely. Others demonstrate properties so broadly useful that engineers across multiple sectors adopt them for entirely different applications. ROHACELL® PMI foam falls firmly in the second category. What…

The transportation industry finds itself at an inflection point. Regulatory pressure to reduce emissions, rising fuel costs, and consumer demand for more efficient vehicles have pushed manufacturers to fundamentally rethink how they build everything from delivery vans to passenger trains.…

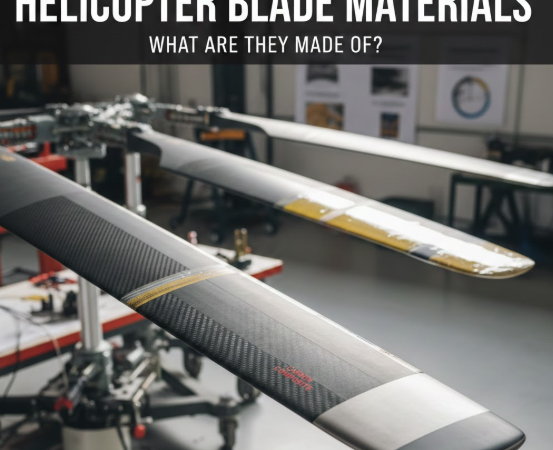

The engineering behind helicopter rotor blades represents one of aviation’s most demanding material science challenges. These components must withstand tremendous centrifugal forces, constant vibration, and fatigue cycles that would destroy most conventional materials within hours. Understanding what goes into modern…