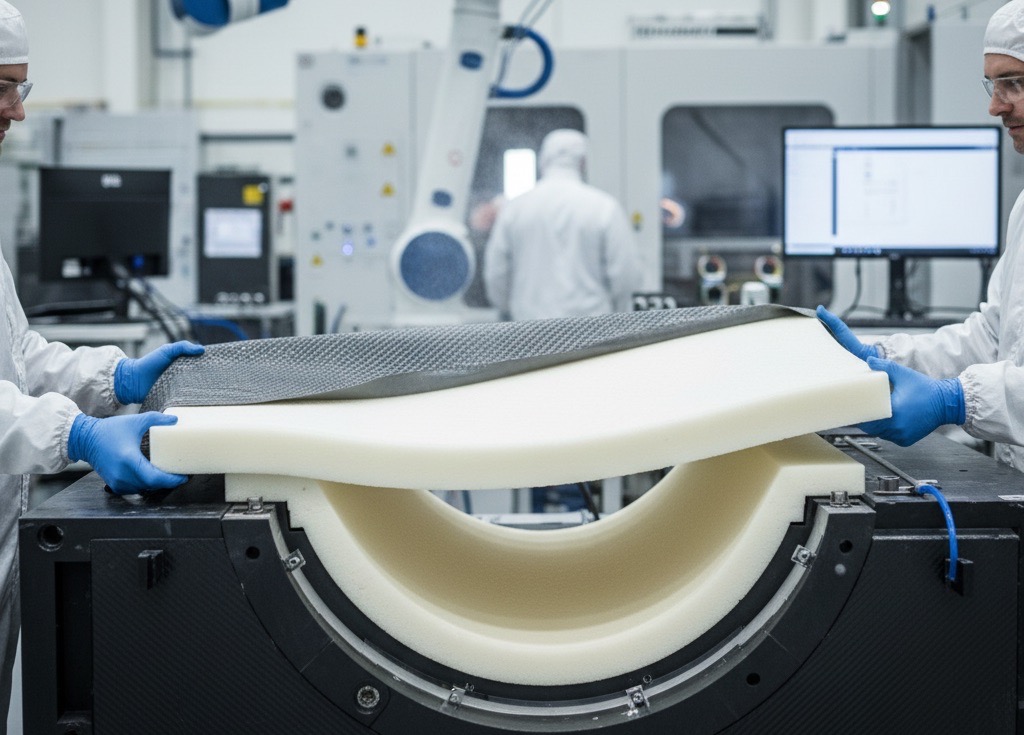

Simple Manufacture of Complex Molded Parts

ROHACELL® PMI foam cores allow relatively simple production of complex molded parts through thermoforming processes. This capability makes ROHACELL® particularly valuable for applications requiring curved or contoured core geometries, such as radomes, fairings, and aerodynamic structures.

Thermoforming Temperature Range

ROHACELL® can be thermoformed at temperatures between 165°C and 205°C. The sheets can be heated using conventional ovens or infrared heaters. Heating duration depends on sheet thickness, with approximately 1 minute per millimeter serving as a general guideline.

Managing Heat Loss During Forming

Due to the low heat capacity of the foam and the expanded surface area created by the open cut cells, ROHACELL® sheets cool rapidly once removed from heating. During transfer from the heating source to the forming device, cooling must be minimized to ensure successful forming.

To counteract rapid heat loss and maintain thermoforming temperature requirements, a protective cover over the heated foam sheet is recommended. Suitable materials include cotton cloth, breather fabric, glass fabric, or silicone rubber covers.

Thermoforming Methods

Three main thermoforming methods can be applied to ROHACELL® foam cores, each suited to different applications and geometries.

Compression Molding uses matched molds to form the heated foam sheet. Both-sided hardened molds offer precise thickness control and can produce both developable and undevelopable curves. Single-sided molds with press machines work well for thicker sheets or larger deformations. One-sided hardened molds combined with soft molds are ideal for developable surface geometries.

Vacuum Forming uses vacuum pressure to draw heated foam against a single-sided mold. This method can produce undevelopable curves and is particularly effective for certain complex geometries, though deformation is somewhat limited by available vacuum force.

Cold-Deforming-Heat-Shaping involves first machining the foam to precise developable dimensions, fixing it to a die using vacuum, then heating in an oven to forming temperature for approximately 1 hour before slow cooling. This method provides excellent process control and may eliminate post-forming machining when positioning is accurate.

Mold Requirements

The high heat resistance requirements for thermoforming molds are relatively modest. Wood, polyester, epoxy resin, or fiberglass molds are all acceptable materials. Once the formed part has cooled to 100°C, it may be removed from the forming mold.

Design Considerations

For shaping core materials, the best results are achieved when deformation is primarily in one dimension, or slight in two dimensions. For complex undevelopable surfaces like radomes, the geometry is typically divided into multiple fan-shaped sections that are thermoformed individually and then bonded together to create the complete core structure.

Expert Support from CHEM-CRAFT

CHEM-CRAFT’s composite engineering team provides technical guidance on thermoforming parameters for all ROHACELL® grades. Contact us for recommendations specific to your application geometry and production requirements.