Marine

LOW RESIN ABSORPTION

Renewable energy

ULTIMATE ENVIRONMENTAL RESISTANCE

Antennas & electronics

LOW ELECTROMAGNETIC RESISTANCE

Medical

HIGH QUALITY COMPOSITES

Automotive

INDUSTRIAL FOAM PROCESSING

Aerospace

LIGHTWEIGHT STRUCTURES

Sport & leisure

ULTIMATE STRENGTH AND FLEXIBILITY

What is ROHACELL®?

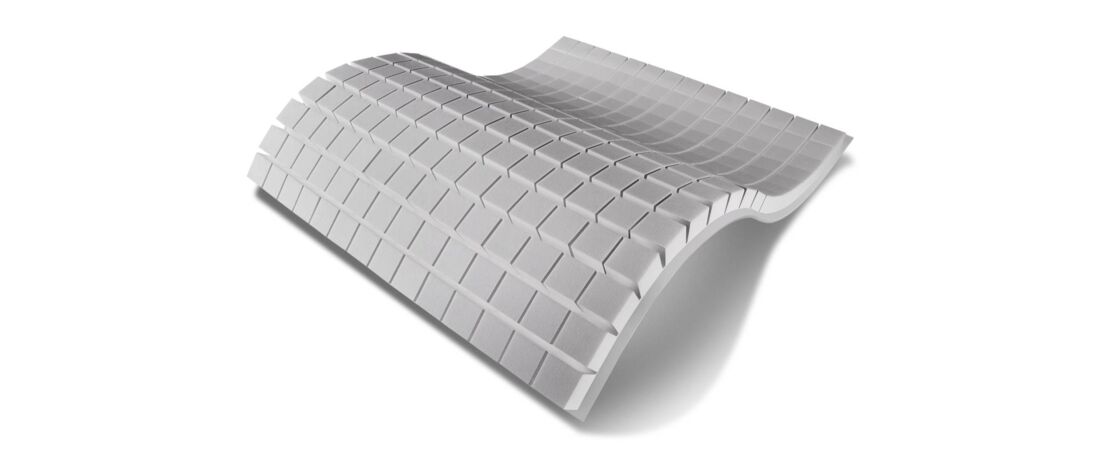

The high-end sandwich core material ROHACELL® PMI foams, produced by Evonik, are a worldwide unique type of polymer foam sheet that is above other producers due to its superior strength to weight ratio combined with high thermal performance and stability.

What is ROHACRYL®?

ROHACRYL® foams, produced by Evonik, are a very new type of acrylic chemistry, allowing high thermal processing up to 120°C, with a very small and closed cell structure assuring very low resin uptake. That results in your weight and cost saving of resin.

HIGH-PRECISION PRODUCTS

Why ROHACELL®?

- Excellent mechanical properties over a wide temperature range, even at low densities

- High temperature resistance up to 200°C

- Unique compressive creep behavior for processing up to 180°C and 0.7 Mpa

- Excellent dynamic strength

- Cell sizes that can be tailored for each processing method

- Excellent mechanical properties over a wide temperature range, even at low densities

- High temperature resistance up to 200°C

- Unique compressive creep behavior for processing up to 180°C and 0.7 Mpa

- Excellent dynamic strength

- Cell sizes that can be tailored for each processing method

HIGH VOLUME APPLICATIONS

Why ROHACRYL®?

- Recyclable structural foam for high volume applications

- High mechanical properties, whear modulus up to 47 MPa

- Very low resin uptake that equals even to 250 g/m2, that saves weight and lowers total raw material costs

- The superior thermal stability of Rohacryl with a value of 120°C make it possible to increase production speed

- Recyclable structural foam for high volume applications

- High mechanical properties, whear modulus up to 47 MPa

- Very low resin uptake that equals even to 250 g/m2, that saves weight and lowers total raw material costs

- The superior thermal stability of Rohacryl with a value of 120°C make it possible to increase production speed

OFFICIAL EVONIK DISTRIBUTOR AND PARTNER

What is CHEM-CRAFT?

CHEM-CRAFT is the leading supplier of ROHACELL® and ROHACRYL® foams in Nordic Europe, Eastern Europe and the BeNeLux countries.

Foams produced by EVONIK Operations GmbH provide impressive mechanical strength and creep compression strength, even at very low densities and a heat distortion temperature.

EVONIK high performance foams are mainly applied to composites industries such as automotive, sports and leisure, transportation, electronics, marine, renewable energy, aerospace and aircraft.

CHEM-CRAFT is the leading supplier of ROHACELL® and ROHACRYL® foams in Nordic Europe, Eastern Europe and the BeNeLux countries.

Foams produced by EVONIK Operations GmbH provide impressive mechanical strength and creep compression strength, even at very low densities and a heat distortion temperature.

EVONIK high performance foams are mainly applied to composites industries such as automotive, sports and leisure, transportation, electronics, marine, renewable energy, aerospace and aircraft.

CHOOSE A RELIABLE PARTNER

Why CHEM-CRAFT?

Chem-Craft consists of a team of composite engineers and experts that are specialized in composite processing methods such as: hand lay-up, RTM, infusion and autoclave. Therefore we have the know-how to distribute ROHACELL® and ROHACRYL® products offering also our suggestions and consulting advice.

Grades we offer:

- ROHACELL® 31 IG-F

- ROHACELL® 51 IG-F

- ROHACELL® 71 IG-F

- ROHACELL® 110 IG-F

- ROHACELL® 31 HF

- ROHACELL® 51 HF

- ROHACELL® 71 HF

- ROHACELL® 51 RIMA

- ROHACELL® 71 RIMA

- ROHACELL® 51 WF

- ROHACELL® 200 WF

- ROHACELL® 71 SL

- ROHACELL® 110 SL

- ROHACELL® 200 SL

- ROHACELL® 71 XT

- ROHACELL® 110 XT

- ROHACRYL® SW 60

- ROHACRYL® SW 80

- ROHACRYL® SW 100

Short lead time

Low minimum order value